DCPS > Forklift Batteries & Industrial Batteries > Forklift Battery Charging

Forklift Battery Charging

- Charging & the 8-8-8 Rule

-

The bread and butter of any warehouse environment is the forklift battery chargers. Industrial battery chargers are great for keeping the batteries in your forklifts and other electric equipment charged up and ready to go. We’ve got a few tips that you can implement today to keep your chargers and batteries moving and working together.

With poor maintenance being the number one cause of battery damage, watching for a few factors can really help to keep your batteries in working order! Make sure that your batteries aren’t running below 80% Depth of Discharge (D.O.D.), being over and under-watered, and being over and under-charged. When you’re watering the batteries, go for distilled water, not non-approved tap water. By choosing distilled water, you’ll help to keep the forklift battery electrolyte at the correct levels. Only add the water to your battery once it has been fully charged. If you’re finding that you need to add water to the battery frequently, it could be a sign of overcharging. Your forklift’s charging system should be checked if you think this is the case. Keeping an eye out for these battery damaging elements can help you and your business get the most life out of your forklift batteries. See our forklift battery maintenance tips.

Remember, batteries love mild climates! Temperatures between 60 to 90 degrees fahrenheit work the best. If the forklift batteries get too cold, it will reduce the amount of power available to you and the batteries could freeze. If they get too hot, there will be electrolyte loss because of evaporation. Along with this, keep your batteries clean and dry. Moisture, dirt, or dust on a battery can keep your battery from charging. This is because the current will try to flow through the grime, from one post to another. Battery connections need to be kept clean as well. The connection surfaces need to be snug fitting, but not so tight that they have to be forced together.

Try not to run your forklift batteries below 20% of use. Running it lower can shorten the lifespan of the battery.

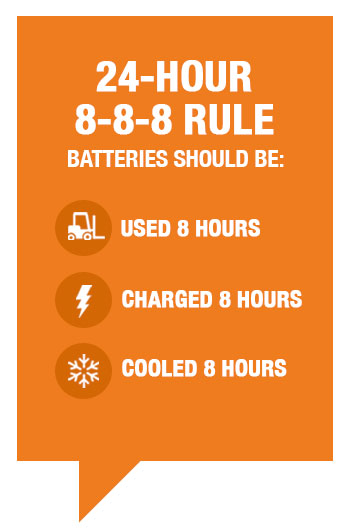

Make sure to give your battery a cool down period after charging. If you aren’t quite sure about the best charging schedule to follow, a great guideline that ensures a proper charging and cool-down time is the 8-8-8 rule. The 8-8-8 rule is a simple and effective way to maintain the charging cycle of your batteries.

The 8-8-8 Rule

During an ideal 24-hour period, batteries should be:

● In use for eight hours

● Charging for eight hours

● Cooling for eight hours

Don't Forget!

Every time you plug your battery in it counts as a charging cycle. Make sure that the cycle charges the forklift battery to full while it’s plugged in.

Chemical reactions are what makes lead acid batteries work. Lead plates and electrolytes interact, which is what keeps the battery running. This isn’t the only chemical reaction that needs to be handled though. There is also hydrogen accumulation, which can be extremely dangerous. Because of these potentially dangerous aspects, battery storage is extremely important and is a major part of battery maintenance. The battery experts at DC Power Solutions can assist you with designing a battery room that ensures the proper ventilation, making your facility safer for everyone by bringing down the risk of a fire or explosion.

Preventative maintenance is a great way to keep your batteries working properly. Scheduled service gives you the peace of mind that your batteries are being checked and maintained by experienced battery technicians who will check on your batteries and keep them watered. Our techs can spot a problem from a mile away and know how to get them fixed quickly so that your forklift batteries will stay up and running.