DCPS > Forklift Batteries & Industrial Batteries > Forklift Batteries

Forklift Batteries

- Reliable, Rechargeable & 98% Recyclable

-

From Voltaic Pile to Forklift Battery

The invention of the forklift battery (lead acid battery), and subsequent advances, tie all the way back to the early invention and pioneering efforts by European physicists Alessandro Volta and Gustav Plante. The electric battery (voltaic pile) was invented 1799 by Alessandro Volta and the rechargeable lead acid battery was created by Gaston Plante in 1859. These scientist-chemists laid the groundwork needed for what would be later used for motive power. There was a buzz of development with the portable elevator patented in 1867, and Ferdinand Porsche's first car (the electric p1) invented in 1898. The "Electric Porter" by Elwell-Parke (1906) was invented to fill the need at the Pennsylvania Railroad's Jersey Terminal for greater efficiency with baggage handling. The lift truck followed in 1914, the Tructractor developed by Clark to move materials at their axle plant, in 1917. The humble yet efficient pallet appearing on the scene in the late 1920s. By the 1930's forklifts were gaining wider use with material handling. Learn more about the history of the forklift battery.

Big, Industrial Batteries: 1,886 lbs. (avg.)

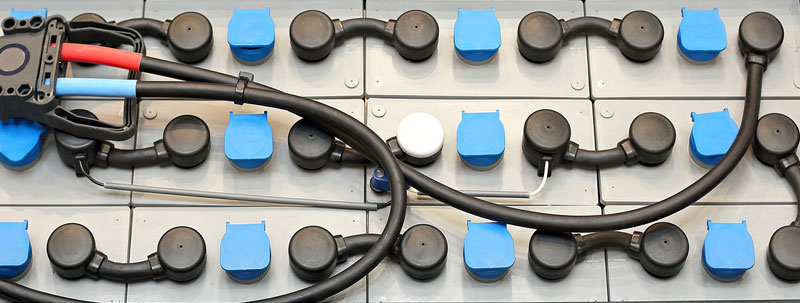

What are forklift batteries? If you've seen a forklift battery you'd know it! Forklift batteries range from a 2-3 feet in a rectangle or square shape depending on the number of cells they have and are powered by science and chemistry using lead plates, and electrolyte. Forklift batteries power warehouse machines like forklifts and lift trucks. The cells that make up forklift batteries are made of lead-coated plates that soak in a water-sulfuric acid (or gel) bath the chemical reaction generates electricity. Forklift batteries are susceptible to vacillating temperatures and may need watering or service to increase their longevity. Extreme temperatures both hot and cold can affect the forklift battery's ability to hold a charge.

Lead Acid Batteries - Science Meets Technology

While lead acid industrial batteries are based on solid technology developed two centuries ago we're carrying on with new developments that blend new technology with old. For example, battery chargers allow warehouses to manage fleets of forklift batteries to keep their forklifts up and running, but that comes with the challenge of keeping the balance of the right charge with rechargeable batteries. DC Power Solutions provides forklift battery preventative maintenance to keep the balance of the water and sulfuric acid where it needs to be, and tests to ensure the cells are holding a charge. DC Power Solutions provides advanced forklift battery technology by peeling back what's going on in your battery with our reporting options. Contact us to get started.

While lead acid industrial batteries are based on solid technology developed two centuries ago we're carrying on with new developments that blend new technology with old. For example, battery chargers allow warehouses to manage fleets of forklift batteries to keep their forklifts up and running, but that comes with the challenge of keeping the balance of the right charge with rechargeable batteries. DC Power Solutions provides forklift battery preventative maintenance to keep the balance of the water and sulfuric acid where it needs to be, and tests to ensure the cells are holding a charge. DC Power Solutions provides advanced forklift battery technology by peeling back what's going on in your battery with our reporting options. Contact us to get started.

What Else Are Forklift Batteries Used For?

While there several things lead acid batteries are regularly used for like motorcycle batteries, scooter batteries, RV batteries, etc., forklift batteries are large enough to use for home electrical storage needs. Some home storage needs include solar electricity storage and off grid energy solutions. Forklift batteries are used as a green. sustainable, solution because lead acid batteries are 98% recyclable which meets the priorities and needs of our communities and businesses. They are also meant for some of the hardest usage in any lead acid application, so even a refurbished lead acid forklift battery can sustain a home for many years at a fraction of the cost of a typical solar battery system.